EWIS TG 1&2

Topics of Course

EWIS TG 1&2

This comprehensive EWIS (Electrical Wiring Interconnection Systems) training program is designed for qualified maintenance personnel responsible for aircraft electrical system maintenance. The course meets EASA AMC 20-21 and AMC 20-22 Appendix C compliance requirements and emphasizes safety-critical procedures developed from lessons learned in aviation electrical incidents.

Course Structure

Module A: General EWIS Practices

• Electrical Safety Fundamentals: Critical current lethality facts (fatal range: 60-70mA), AC vs DC hazards, first aid procedures

• Power Application Procedures: Pre-energizing safety checks, circuit isolation protocols, lock-out/tag-out procedures

• Safety Warnings: Understanding AMM warning classifications (NOTE/CAUTION/WARNING) and circuit breaker protection principles

• Human Factors: The "Dirty Dozen" error factors and risk mitigation strategies

• ESD Protection: Static discharge sources, soft vs hard failures, wrist strap requirements, workbench grounding protocols

Module B: Wiring Practices Documentation

• Documentation Hierarchy: AMM, IPC, ESPM, and AWM navigation and application

• ATA-100 Organization: Chapter-section-subsection structure and page block navigation

• Effectivity Management: Critical importance of serial number and modification effectivity

• Wiring-Specific Manuals: WDM point-to-point identification, AWL effectivity tracking, ESPM repair procedures

Module C: Inspection Procedures

• Inspection Types: General Visual (GVI), Detailed (DI), and Enhanced Zonal Analysis Procedure (EZAP)

• Critical Areas: Wiring installation points, common defects, damage recognition

• Assessment Techniques: Contamination identification, damage categorization, human factors in inspection

Module D: Housekeeping and Contamination Control

• Contamination Sources: Internal (hydraulic/engine oils, fuel, galley spillage) and external (de-ice fluids, weather, FOD)

• Classification Systems: Natural, accidental, and age-related contamination

• Cleaning Procedures: Soft brush/vacuum techniques, pressure washing precautions, solvent limitations

• "Protect and Clean as You Go" philosophy implementation

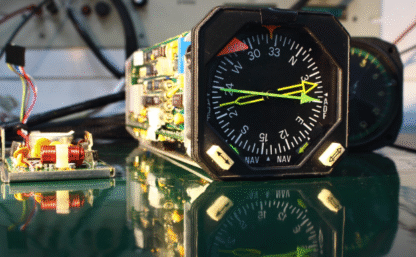

Module E: Wire Systems and Components

• Wire Classifications: Standard, fire-resistant, screened/quad cables, aluminum applications

• Installation Standards: Bundle installation, clamp selection, protection requirements

• Damage Assessment: High-risk area identification, repair procedures, quality standards

Module F: Connective Devices

• Connector Types: Threaded connectors, coupling mechanisms, identification systems

• Terminal Blocks: Non-modular designs, lug stacking procedures, strain relief requirements

• Connection Quality: Installation techniques, environmental considerations

Module G: Electrical Bonding and Grounding

• Bonding Fundamentals: Primary vs secondary bonding, lightning protection, HIRF protection

• System Design: Metallic vs composite aircraft considerations, cage systems

• Maintenance Requirements: Connection specifications, inspection procedures, testing protocols

Key Learning Outcomes

Upon completion, participants will be able to:

• Apply critical electrical safety procedures to prevent injury and equipment damage

• Navigate and interpret complex EWIS documentation accurately

• Perform systematic inspections using appropriate techniques and standards

• Implement effective contamination control measures

• Select, install, and maintain wire systems according to aviation standards

• Properly service connective devices and bonding systems

• Recognize and assess various types of electrical system damage

Assessment and Certification

• Written Examination: 80% pass mark required

• Practical Demonstrations: Hands-on skill verification

• Safety Acknowledgment: Formal recognition of safety responsibilities

• Refresher Training: Required every 2 years

Safety Emphasis

The course heavily emphasizes that electrical current can be lethal at surprisingly low levels (less than a standard light bulb uses), and that every EWIS procedure exists because of lessons learned from tragedies like TWA 800. Professional attention to these procedures directly impacts flight safety and passenger protection.

Duration: Multi-day intensive program with both theoretical and practical components Compliance: EASA AMC 20-21 and AMC 20-22 Appendix C certified

MODULE A: GENERAL EWIS PRACTICES TG 1&2

1.1 SAFETY PRACTICES

Electrical Safety Fundamentals

Current Lethality - The Critical Facts You Must Know

The Human Body and Electrical Current

• Your body is essentially a conductor with varying resistance (1,000-100,000 ohms)

• Wet conditions dramatically reduce body resistance, increasing danger

• Fatal Current Range: 0.06A to 0.07A (60-70 milliamps)

o This is less current than a standard 100W light bulb uses

o Death occurs through ventricular fibrillation (heart stops pumping effectively)

Current Effects on the Human Body:

• 1-5 mA: Barely perceptible, no harm

• 5-10 mA: Painful shock, muscular control not lost

• 10-20 mA: Muscular control lost, "can't let go" current

• 20-50 mA: Respiratory paralysis, severe muscular contractions

• 50-100 mA: Ventricular fibrillation (usually fatal)

• 100-200 mA: Certain ventricular fibrillation and death

AC vs DC Hazards - Critical Differences for Maintenance Personnel

AC (Alternating Current) Hazards:

• More dangerous than DC at the same voltage level

• Causes sustained muscular contractions

• "Can't let go" effect occurs at lower currents

• 60Hz frequency (standard aircraft AC) is particularly dangerous to heart rhythm

• Example: 115V AC aircraft power can easily exceed fatal current levels

DC (Direct Current) Hazards:

• Causes single muscular contraction, often throwing victim clear

• Generally, requires higher voltage to cause same damage as AC

• 28V DC aircraft systems still dangerous in wet conditions

• Battery systems can deliver very high currents

Practical Maintenance Implications:

• Always treat 115V AC aircraft systems as potentially lethal

• 28V DC systems require equal caution in wet/damp conditions

• Ground power units deliver both AC and DC - know which you're working with

First Aid Procedures for Electrical Shock

Immediate Actions (First 60 seconds are critical):

1. DO NOT touch the victim while still energized

2. Shut off power source immediately

o Pull main breaker/disconnect

o Unplug equipment

o Contact ground crew for external power disconnect

3. Call for emergency medical help immediately

4. Check for responsiveness and breathing

If victim is unconscious but breathing:

• Place in recovery position

• Monitor breathing and pulse continuously

• Keep warm but not hot

• Prepare for CPR if breathing stops

If victim is not breathing:

• Begin CPR immediately

• Continue until medical help arrives

• Do not give up - electrical shock victims have been revived after extended periods

What NOT to do:

• Do not move victim unless in immediate danger

• Do not give water or any liquids

• Do not apply ice or extreme cold

• Do not assume minor shock means no injury - internal damage may not be apparent

Power Application Procedures

Pre-energizing Safety Checks (AMM TASK 24-41-00-861-002-A)

Mandatory Pre-Power Checklist:

Before ANY electrical power is applied:

1. Verify all maintenance circuits are isolated

o Check all opened circuit breakers are locked/tagged

o Confirm no active maintenance on electrical systems

o Review work orders for electrical system involvement

2. Personnel Notification Protocol:

o Announce "POWERING UP AIRCRAFT" over hangar communication

o Ensure all personnel are clear of moving components

o Verify no one is working in energized areas

3. External Power Unit Verification:

o Check GPU voltage and frequency settings

o Verify correct cable connections (AC/DC)

o Test GPU ground connection integrity

WARNING Implementation: "MAKE SURE THAT ALL THE CIRCUITS IN MAINTENANCE ARE ISOLATED BEFORE YOU SUPPLY ELECTRICAL POWER TO THE AIRCRAFT. UNWANTED ELECTRICAL POWER CAN BE DANGEROUS."

This isn't just a warning - it's a life-saving procedure that has prevented countless accidents.

Circuit Isolation Requirements

Complete Isolation Protocol:

Before Starting Maintenance:

1. Attach grounding wire to aircraft

o Use proper grounding point as specified in AMM

o Verify ground connection integrity with bonding tester

o Maintain ground throughout maintenance activity

2. De-energize electrical system systematically:

o External power OFF

o Battery master OFF

o Individual system breakers OFF (as required)

3. Physical isolation of circuits:

o Install lock-clips on each opened circuit breaker

o Use bright-colored collars for visibility

o Apply warning tags at multiple locations

After Maintenance Completion:

1. Systematic power restoration:

o Verify cause of original component failure eliminated

o Check all switches in safe positions

o Remove all tags and clips

o Inform all personnel before energizing

o Energize systems progressively

Lock-out/Tag-out (LOTO) Procedures

Physical Locking Requirements:

• Use approved lock-clips on circuit breakers

• Each technician applies their own personal lock

• Only the person who applied the lock may remove it

• Use standardized tags with clear identification

Tag Information Must Include:

• Technician name and badge number

• Date and time of isolation

• Reason for isolation

• Expected completion time

• Contact information

Critical Rule: Never remove another technician's LOTO device, even if they're not present.

Safety Warnings and Procedures

AMM Warning Classifications

Understanding the Three-Level System:

NOTE (Blue Text/Background):

• Provides best practice or efficient procedures

• Example: "NOTE: Use torque wrench for consistent results"

• Ignoring may result in suboptimal work quality

CAUTION (Yellow Text/Background):

• Procedure that prevents equipment/aircraft damage

• Example: "CAUTION: Do not exceed 50 lb-ft torque - component damage may occur"

• Ignoring results in costly repairs/component replacement

WARNING (Red Text/Background):

• Procedure that prevents personal injury or death

• Example: "WARNING: Isolate electrical power before maintenance"

• Ignoring can result in serious injury or fatality

Maintenance Professional Response:

• NOTE: Follow for best results

• CAUTION: Follow to prevent expensive mistakes

• WARNING: Follow to save lives

Circuit Breaker Protection Principles

Circuit Breakers Protect the WIRE, Not the Equipment

Key Understanding:

• Circuit breakers are sized for wire ampacity, not load requirements

• They prevent wire overheating and potential fire

• Tripped breaker indicates current overload condition

• Never replace breaker with higher amperage rating

Practical Application:

• 20A breaker protects 20A-rated wire

• Equipment may only use 15A, but wire can safely carry 20A

• Breaker trips at 20A to prevent wire damage

• This principle prevents electrical fires like TWA 800

Practical Exercise: Landing Light Replacement Safety

Complete Safety Setup Procedure:

Step 1: Risk Assessment

• Identify high-voltage circuits (28V DC, 115V AC)

• Check for fuel contamination risk

• Assess moving component hazards

Step 2: Physical Safety Barriers

• Install safety barriers around work area

• Post warning notices in cockpit: "DO NOT OPERATE LANDING LIGHTS"

• Secure any movable components

Step 3: Electrical Isolation

• Locate and open landing light circuit breakers

• Install safety clips on each breaker

• Tag breakers with warning notices

• Test circuits de-energized with voltmeter

Step 4: Additional Precautions

• Check for fuel contamination in light assembly

• If fuel present: Do not operate until leak repaired and assembly cleaned

• Install conductive dust caps on disconnected connectors

Human Factors

The "Dirty Dozen" Error Factors

Critical for EWIS Maintenance:

1. Lack of Communication

o Failed shift handovers leading to incomplete isolation

o Not informing team of electrical system status

2. Complacency

o "I've done this a thousand times" - leads to skipped safety steps

o Routine maintenance becomes automatic without conscious safety checks

3. Lack of Knowledge

o Not understanding current lethality

o Inadequate familiarity with specific aircraft systems

4. Distraction

o Working on electrical systems while thinking about other problems

o Interruptions during critical safety procedures

5. Lack of Teamwork

o Working alone on electrical systems without backup safety observer

o Not coordinating with other trades on same aircraft

6. Fatigue

o Impaired judgment during electrical isolation procedures

o Reduced attention to detail during safety checks

7. Lack of Resources

o Using wrong tools for electrical work

o Working without proper safety equipment

8. Pressure

o Rushing electrical work due to schedule demands

o Skipping safety steps to save time

9. Lack of Assertiveness

o Not speaking up when safety procedures are compromised

o Following improper instructions from supervisors

10. Stress

o Personal problems affecting concentration during electrical work

o High-pressure situations leading to shortcuts

11. Lack of Awareness

o Not recognizing electrical hazards in work environment

o Failure to identify changing conditions

12. Norms

o "Everyone does it this way" - even if wrong

o Accepting substandard safety practices as normal

Risk Mitigation Strategies

Personal Strategies:

• Always use buddy system for electrical work

• Take breaks during complex electrical troubleshooting

• Speak up immediately when safety is compromised

• Follow procedures exactly, even under pressure

Team Strategies:

• Brief all team members on electrical hazards before work begins

• Establish clear communication protocols

• Implement mandatory safety pauses for electrical work

• Cross-check each other's safety procedures

1.2 ELECTROSTATIC DISCHARGE SENSITIVE DEVICES (ESDS)

ESD Sources and Effects

Understanding Static Electricity in Aircraft Maintenance

How Static Charges Build Up:

• Walking across carpeted hangar floors: 35,000V possible

• Sliding across aircraft seats: 18,000V

• Handling plastic covers/bags: 20,000V

• Peeling tape: 9,000V

• Normal body movement: 3,000-5,000V

You Cannot Feel Static Discharge Below 3,500V

• Most electronic damage occurs at 100-1,000V

• You're damaging components without knowing it

• Humidity affects static buildup (dry air = more static)

Soft vs Hard Failures

Hard Failures (Immediate):

• Component completely stops working

• Easy to detect during installation testing

• Examples: Burnt resistors, blown diodes

• Immediate replacement required

Soft Failures (Delayed/Intermittent):

• Component appears to work initially

• Fails weeks or months later during flight

• Most dangerous type - affects flight safety

• Examples: Weakened semiconductors, damaged integrated circuits

• May cause intermittent system faults

The Hidden Cost:

• Soft failures are estimated to be 10 times more common than hard failures

• Result in costly "No Fault Found" removals

• Can cause in-flight system failures

• Much harder to troubleshoot

Static Charge Buildup Mechanisms

Primary Sources in Aircraft Maintenance:

Triboelectric Charging:

• Occurs when two materials separate after contact

• Common combinations in aircraft maintenance:

o Plastic tools on metal surfaces

o Synthetic clothing on aircraft skin

o Plastic covers on electronic equipment

Induction Charging:

• Occurs near strong electrical fields

• Common sources:

o Radar systems (even when not transmitting)

o Radio transmitters

o Power supply units

Environmental Factors:

• Low humidity (below 40%) increases static buildup

• Air conditioning systems reduce humidity

• Winter conditions are worst for static buildup

2.2 ESDS Protection Procedures

Wrist Strap Requirements

1MΩ Minimum Resistance - Why This Matters:

Safety Protection:

• Prevents dangerous current flow through body

• If you contact live electrical circuit, wrist strap limits current to safe level

• Without resistor: potentially lethal current path to ground

Equipment Protection:

• Provides controlled discharge path for static electricity

• Slow discharge prevents component damage

• Fast discharge (low resistance) can still damage sensitive components

Daily Wrist Strap Testing:

1. Visual inspection: Check for cuts, frays, or damage

2. Resistance test: Must read 1MΩ ±10%

3. Continuity test: Verify connection from wrist to ground point

4. Record results: Log testing in maintenance records

Proper Wrist Strap Wearing:

• Direct skin contact (not over clothing)

• Snug fit but not tight enough to restrict circulation

• Connect to verified ground point before handling ESDS components

• Keep connected throughout entire work period

Workbench Grounding Protocols

ESD-Safe Work Surface Requirements:

Primary Work Surface:

• Dissipative material (not conductive)

• Surface resistance: 10⁶ to 10⁹ ohms

• Must be grounded through 1MΩ resistor

• Clean with approved ESD-safe cleaners only

Ground Connection Verification:

• Test ground connection daily

• Verify less than 1Ω resistance to aircraft ground

• Use only approved grounding points

• Document ground verification

Work Area Setup:

• Remove all non-essential plastic materials

• Use only ESD-safe tools and containers

• Maintain 40-60% relative humidity when possible

• Post ESD warning signs in work area

Handling and Packaging Procedures

Component Removal:

1. Verify ESD protection active (wrist strap, grounded surface)

2. Power OFF and verified with test equipment

3. Install conductive dust caps immediately upon disconnection

4. Place component in anti-static bag within 30 seconds

5. Seal bag properly with anti-static tape

Component Installation:

1. Verify ESD protection active

2. Remove component from bag at workstation (not at aircraft)

3. Handle only by non-sensitive areas (case, mounting points)

4. Never touch pins, connectors, or circuit boards

5. Install dust caps on aircraft connectors until connection made

Critical Rule: Once component is removed from protective packaging, either install it immediately or return it to ESD-safe storage.

LRU Replacement Practices

Conductive Dust Cap Installation

Why Conductive Dust Caps are Essential:

• Prevent static charge buildup on connector pins

• Protect against moisture and contamination

• Maintain proper impedance in RF circuits

• Prevent accidental contact with energized pins

Proper Installation Procedure:

1. Select correct cap size and type

2. Verify cap is clean and undamaged

3. Install immediately after connector separation

4. Push firmly but do not over-tighten

5. Verify secure installation

Cap Material Requirements:

• Conductive material (usually carbon-filled plastic)

• Resistance less than 10⁴ ohms

• Compatible with connector type

• Resistant to aircraft fluids and temperature extremes

Anti-Static Procedures During LRU Work

Step-by-Step LRU Removal:

Preparation:

• Review AMM procedures for specific LRU

• Gather all required ESD-safe tools

• Set up grounded work area

• Don wrist strap and verify connection

Power Isolation:

• Remove electrical power per AMM

• Verify de-energized with appropriate test equipment

• Install circuit breaker locks and tags

• Wait specified time for capacitor discharge

Physical Removal:

• Install dust caps on aircraft connectors first

• Disconnect LRU connectors using proper techniques

• Support LRU weight during removal

• Never allow LRU to swing on remaining connections

Post-Removal:

• Install dust caps on all LRU connectors

• Place LRU in anti-static packaging

• Complete removal documentation

• Store in ESD-safe area

LRU Installation (Reverse Process):

• Remove LRU from packaging at workstation

• Carry in anti-static container to aircraft

• Remove dust caps just before connection

• Follow AMM torque specifications

• Perform operational tests per AMM

1.3 TOOLS AND EQUIPMENT

Specialized EWIS Tools

Wire Strippers and Preparation Tools

Manual Wire Strippers:

• Gauge-specific strippers: Prevent conductor damage

• Adjustable strippers: Verify setting before each use

• Automatic strippers: Consistent strip length, reduced hand fatigue

Critical Technique Points:

• Strip length must match specification (typically 0.25" for most terminals)

• No conductor damage: Stripping should not reduce conductor diameter

• Clean cut: No frayed or twisted conductor ends

• Consistent results: Same strip length on all wires in bundle

Wire Preparation Beyond Stripping:

• Conductor cleaning: Remove oxidation with approved cleaners

• Conductor twisting: For stranded wire, twist clockwise

• Insulation inspection: Check for cracks or damage beyond strip area

• Length verification: Measure total length against AMM requirements

Crimping Tools (Manual and Pneumatic)

Manual Crimping Tools:

• Ratcheting action: Prevents incomplete crimps

• Proper die selection: Must match terminal and wire gauge

• Inspection windows: Allow visual verification of crimp quality

• Calibration requirements: Monthly verification of crimp dimensions

Pneumatic Crimping Tools (e.g., Pico Model 500D):

• Air pressure requirements: 6-9 bars clean, dry air

• Full-cycle operation: Cannot open until complete crimp cycle finished

• Die selection critical: Each wire gauge requires specific die

• Quality advantages: Consistent pressure, repeatable results

Crimp Quality Inspection:

• Visual inspection: Uniform compression, no cracks

• Dimension check: Use go/no-go gauges

• Pull test: Verify mechanical strength (when required)

• Electrical test: Verify continuity and resistance

Common Crimping Errors:

• Wrong die size for wire gauge

• Incomplete crimp cycle

• Wire insulation in crimp area

• Multiple wires in single-wire terminal

Heat Shrink Application Equipment

Heat Gun Operation:

• Temperature control: 200-300°C for most aircraft applications

• Even heating: Keep gun moving to prevent hot spots

• Proper distance: 6-8 inches from work surface

• Shrinkage verification: Complete when wrinkled surface becomes smooth

Heat Shrink Tubing Selection:

• Shrink ratio: Typically, 2:1 or 3:1 for aircraft use

• Wall thickness: Must provide adequate protection

• Adhesive-lined: Required for moisture sealing

• Temperature rating: Must exceed application environment

Installation Procedure:

1. Select proper size: Before shrinking, tubing should fit loosely over connection

2. Position correctly: Center over connection with equal overlap

3. Apply heat evenly: Start from center and work outward

4. Verify complete shrinkage: No wrinkles, uniform appearance

5. Cool before handling: Allow complete cooling before moving

Tool Calibration and Maintenance

Calibration Requirements and Schedules

Why Calibration Matters in EWIS Work:

• Torque specifications prevent loose connections and over-stress

• Crimp dimensions ensure electrical and mechanical integrity

• Test equipment accuracy affects troubleshooting reliability

• Regulatory compliance requires calibrated tools for airworthiness

Standard Calibration Intervals:

• Torque wrenches: Every 6 months or 5,000 operations

• Crimping tools: Every 3 months or when suspect

• Multimeters: Annually

• Insulation testers: Annually

• Bonding testers: Every 6 months

Calibration Documentation Requirements:

• Calibration certificate with actual readings

• Traceability to national standards

• Due date clearly marked on tool

• Calibration sticker or tag

Pre-Use Inspection Checklists

Daily Tool Inspection (Before First Use):

Visual Inspection:

• Check for physical damage (cracks, dents, wear)

• Verify calibration sticker present and current

• Inspect electrical cords for damage

• Check moving parts for smooth operation

Functional Check:

• Verify tool operates within normal parameters

• Check digital displays for proper operation

• Test safety features (guards, switches)

• Verify all accessories present and undamaged

Documentation:

• Record inspection results

• Report any deficiencies immediately

• Remove defective tools from service

• Tag defective tools "DO NOT USE"

Critical Rule: Any tool that fails inspection must be removed from service immediately and tagged.

Tool Removal Criteria

Immediate Removal Situations:

• Overdue calibration: No exceptions, even if "just expired"

• Physical damage: Cracks, excessive wear, broken parts

• Erratic operation: Inconsistent readings, intermittent operation

• Safety feature failure: Guards, emergency stops, insulation

Documentation Process:

1. Tag tool "OUT OF SERVICE"

2. Remove from tool room/work area

3. Complete deficiency report

4. Notify tool control personnel

5. Arrange repair or replacement

Return to Service Requirements:

• Repair by authorized facility

• Re-calibration with current certificate

• Functional verification test

• Documentation update

• Tool control approval

Troubleshooting Equipment

Bonding Testers and Duplex Hand Spikes

Why Four-Wire Testing is Required:

• Very low resistance measurements (milliohms)

• Two wires carry test current

• Two wires measure voltage drop

• Eliminates test lead resistance from measurement

Duplex Hand Spike Positioning:

• Current poles (C1, C2): Outer contacts, provide test current

• Potential poles (P1, P2): Inner contacts marked "P", measure voltage

• Critical rule: P contacts must always be adjacent to each other

• Contact pressure: Firm pressure required for accurate readings

Bonding Test Procedure:

1. Clean contact points: Remove paint, corrosion, contamination

2. Position spikes correctly: P contacts adjacent, good contact pressure

3. Apply test current: Typically 10A for aircraft bonding tests

4. Read resistance: Should be less than 2.5 milliohms for primary bonding

5. Document results: Record reading and test locations

Common Bonding Test Errors:

• Incorrect spike positioning

• Poor contact pressure

• Contaminated contact points

• Wrong test current setting

Insulation Testers

High Voltage Safety Precautions:

• Wiring must be isolated: No power applied during test

• Disconnect equipment: Remove all connected equipment

• Personnel safety: Never touch wiring during test

• Warning signs: Post high voltage warning signs

Test Voltage Selection:

• Low voltage systems (28V DC): Test at 500V DC

• 115V AC systems: Test at 1000V DC

• High voltage systems: Consult AMM for specific requirements

• Never exceed specified test voltage: Can damage wire insulation

Insulation Test Procedure:

1. Isolate circuit completely: Remove power, disconnect equipment

2. Select appropriate test voltage

3. Connect tester leads to circuit

4. Apply test voltage for specified time (typically 60 seconds)

5. Read insulation resistance (typically >10 megohms)

6. Discharge circuit safely before disconnecting tester

Interpreting Results:

• Good insulation: >10 megohms

• Marginal: 1-10 megohms (investigate further)

• Poor: <1 megohm (repair required)

• Trending: Compare with previous readings

Safety Protocols for Test Equipment Use

Before Using Any Test Equipment:

1. Verify equipment calibration current

2. Inspect test leads for damage

3. Review AMM procedures for specific test

4. Ensure proper personal protective equipment

5. Verify circuit isolation

During Testing:

1. Follow lockout/tagout procedures

2. Use proper test lead connections

3. Never modify test procedures

4. Monitor for unsafe conditions

5. Stop immediately if problems occur

After Testing:

1. Safely discharge any stored energy

2. Remove test equipment properly

3. Restore circuit to normal configuration

4. Document all test results

5. Report any abnormal findings

Practical Exercises and Demonstrations

Exercise 1: ESD Protection Setup

Set up complete ESD-safe work area

• Test wrist strap resistance

• Demonstrate proper component handling

Exercise 2: Wire Stripping and Crimping

• Strip various wire gauges to specification

• Perform crimp using manual and pneumatic tools

• Inspect crimp quality using go/no-go gauges

Exercise 3: Bonding Test Simulation

• Set up bonding tester with duplex hand spikes

• Practice proper spike positioning

• Interpret test results

Exercise 4: Safety Scenario Response (10 minutes)

• Simulate electrical shock emergency

• Practice proper first aid response

• Demonstrate circuit isolation procedures

Assessment Questions

1. What is the fatal current range for humans?

2. Why is 1MΩ resistance required in ESD wrist straps?

3. What are the three types of AMM warnings and their meanings?

4. When must tools be removed from service?

5. Why do bonding testers require four-wire connections?

6. What is the difference between soft and hard ESD failures?

7. List the five critical steps in LRU removal procedure.

8. What test voltage is used for 28V DC circuit insulation testing?

Key Takeaways for Target Groups 1+2

Safety is Not Negotiable:

• Electrical current can kill at levels much lower than you might think

• Every electrical procedure has life-safety implications

• Your actions affect not just you, but everyone who flies in that aircraft

Professional Standards:

• Use only calibrated, properly maintained tools

• Follow procedures exactly - they're written in blood

• When in doubt, stop and ask for guidance

• Document everything properly

Continuous Learning:

• Technology changes, but safety principles remain constant

• Stay current with AMM updates and procedure changes

• Learn from incidents and near-misses

• Share knowledge with your team

Remember TWA 800: Every EWIS procedure we follow today exists because of lessons learned from that tragedy. Your careful attention to these procedures helps ensure it never happens again.

Module B: Wiring Practices Documentation

Why Documentation Mastery is Critical for EWIS Maintenance

The Life-Safety Connection:

• Wrong wire identification can lead to electrical fires

• Incorrect repair procedures can cause system failures in flight

• Outdated documentation has led to maintenance-induced incidents

• Your ability to navigate and interpret documentation directly affects flight safety

Professional Responsibility: As a qualified maintenance technician, you are legally responsible for ensuring:

• All work follows current, approved documentation

• Proper procedures are followed exactly as written

• Correct parts and materials are used

• All regulatory requirements are met

The Cost of Documentation Errors:

• Aircraft on ground (AOG) situations costing thousands per hour

• Rework due to incorrect procedures or parts

• Potential regulatory violations and certificate actions

• Most importantly: Risk to passenger and crew safety

-

WIRING DIAGRAM MANUAL (WDM)

-

AIRCRAFT WIRING LIST (AWL)

-

ESPM APPLICATIONS

MODULE C: INSPECTION PROCEDURES

Electrical Wiring Interconnection Systems (EWIS) inspection forms the backbone of aviation electrical safety. As aircraft become increasingly complex with sophisticated electrical systems, the integrity of wiring installations becomes critical to flight safety. This module focuses on systematic inspection procedures that ensure electrical systems remain airworthy throughout an aircraft's operational life.

The inspection of EWIS requires specialized knowledge, proper techniques, and an understanding of potential failure modes. Unlike mechanical components that may show obvious signs of wear, electrical system degradation often occurs gradually and may not be immediately apparent. This makes systematic inspection procedures essential for maintaining aviation safety standards.

-

INSPECTION TYPES AND STANDARDS

-

CRITICAL INSPECTION AREAS

-

DAMAGE ASSESSMENT AND RECOGNITION

MODULE D: HOUSEKEEPING AND CONTAMINATION CONTROL

Contamination control represents one of the most critical yet often overlooked aspects of electrical wiring interconnection system maintenance. Unlike mechanical components that may continue to function despite surface contamination, electrical systems are highly sensitive to foreign materials that can create conductive paths, degrade insulation properties, or accelerate corrosion processes. The consequences of inadequate contamination control can range from intermittent system malfunctions to catastrophic electrical fires.

Modern aircraft operate in diverse environments, from humid tropical conditions to arctic temperatures, from dusty desert airfields to salt-laden coastal airports. Each environment presents unique contamination challenges that must be understood and managed through systematic housekeeping procedures. The complexity of contamination control is further increased by the variety of materials and fluids used in aircraft operation and maintenance, many of which can have adverse effects on electrical components.

Effective contamination control requires understanding not only the sources and types of contamination but also the mechanisms by which contaminants affect electrical systems. This knowledge forms the foundation for developing appropriate cleaning procedures and implementing preventive measures that maintain system integrity throughout the aircraft's operational life.

-

CONTAMINATION SOURCES AND TYPES

-

CONTAMINATION CLASSIFICATION

-

CLEANING PROCEDURES AND SAFETY

MODULE E: WIRE SYSTEMS AND COMPONENTS

Introduction to Aviation Wire Systems

Wire systems form the nervous system of modern aircraft, carrying electrical power and signals between components distributed throughout the airframe. Unlike automotive or residential electrical systems, aviation wire systems must operate reliably in extreme environments while meeting stringent weight and space constraints. The selection, installation, and maintenance of these systems requires specialized knowledge of materials, construction techniques, and operational requirements unique to the aviation environment.

The evolution of aircraft electrical systems has driven continuous advancement in wire technology, from simple single-conductor installations in early aircraft to complex multi-layer harnesses carrying hundreds of circuits in modern commercial transports. This evolution has been accompanied by increasingly sophisticated requirements for fire resistance, electromagnetic compatibility, and environmental protection that challenge traditional approaches to electrical system design and maintenance.

Understanding wire systems requires appreciation of the interdisciplinary nature of aviation electrical installations. Mechanical considerations such as vibration resistance and thermal expansion must be balanced against electrical requirements for signal integrity and power transmission capability. Environmental factors including temperature extremes, chemical exposure, and moisture ingress, add additional complexity to system design and maintenance procedures.

-

WIRE TYPES AND CONSTRUCTION

-

INSTALLATION PRACTICES

-

DAMAGE ASSESSMENT AND REPAIR

MODULE F: CONNECTIVE DEVICES

Connective devices serve as the critical interfaces within aircraft electrical systems, enabling the distribution of power and signals while providing the flexibility necessary for maintenance, system expansion, and component replacement. Unlike permanent electrical connections, connective devices must maintain reliable electrical contact through thousands of connection and disconnection cycles while withstanding the demanding environmental conditions encountered in aircraft operation.

The reliability of connective devices directly impacts aircraft safety and operational efficiency. A single connector failure can disable critical aircraft systems, while intermittent connection problems can create troubleshooting challenges that result in extended maintenance delays and potential safety hazards. Understanding the design principles, proper installation techniques, and maintenance requirements of connective devices is essential for maintaining aircraft electrical system integrity.

Modern aircraft utilize hundreds or even thousands of connective devices, ranging from simple two-pin connectors for basic circuits to complex multi-pin connectors carrying dozens of different signals and power levels. The diversity of connector types reflects the wide range of electrical requirements found in aircraft systems, from high-current power distribution to sensitive data transmission applications requiring precise impedance control and electromagnetic shielding.

The evolution of aviation connective devices has been driven by increasing system complexity, miniaturization requirements, and the need for improved reliability in harsh environments. Early aircraft connectors were often adapted from commercial or military applications, but modern aviation connectors are purpose-designed to meet the unique requirements of aircraft installations, including weight limitations, vibration resistance, and environmental sealing requirements.

-

CONNECTOR TYPES AND IDENTIFICATION

-

TERMINAL BLOCKS AND CONNECTIONS

MODULE G: ELECTRICAL BONDING AND GROUNDING

Introduction to Aircraft Electrical Bonding and Grounding

Electrical bonding and grounding systems form the invisible foundation upon which all aircraft electrical systems depend for safe and reliable operation. These systems provide multiple critical functions including personnel safety, equipment protection, electromagnetic compatibility, and lightning strike protection. Unlike ground-based electrical systems that can utilize earth ground as a reference, aircraft electrical systems must create their own comprehensive grounding network that remains effective throughout all phases of flight operation.

The complexity of modern aircraft bonding systems reflects the sophisticated electrical and electronic systems they must support. A typical commercial transport aircraft may contain hundreds of bonding connections, each serving specific functions ranging from basic electrical return paths to specialized electromagnetic interference suppression. The failure of even a single critical bonding connection can compromise multiple aircraft systems and create potential safety hazards.

Understanding aircraft bonding and grounding requires appreciation of the multiple physical phenomena these systems must address. Electrical bonding provides low-resistance paths for current flow, electromagnetic bonding creates continuous conductive surfaces for radio frequency energy management, and electrostatic bonding prevents the accumulation of static charges that could cause fires or explosions. Each of these functions may require different bonding techniques and materials, making system design and maintenance a complex interdisciplinary challenge.

The evolution of aircraft bonding systems has been driven by increasing electrical system complexity, more stringent electromagnetic compatibility requirements, and lessons learned from electrical system failures and lightning strike incidents. Modern bonding requirements reflect decades of operational experience and extensive testing that have identified the critical factors affecting bonding system performance in the demanding aircraft environment.

-

BONDING FUNDAMENTALS

-

BONDING MAINTENANCE

Your Instructor

gagisa007@gmail.com

Follow Me: